SCADA Systems Meet AIDC: Unlocking Real-Time Control and Traceability

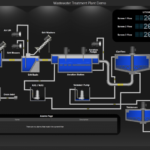

Modern industries rely on a mix of automation and real-time data to keep operations efficient, safe, and reliable. At the heart of this is SCADA—short for Supervisory Control and Data Acquisition. Whether in energy, water treatment, transportation, or manufacturing, SCADA systems serve as the central nervous system of industrial processes.

Modern industries rely on a mix of automation and real-time data to keep operations efficient, safe, and reliable. At the heart of this is SCADA—short for Supervisory Control and Data Acquisition. Whether in energy, water treatment, transportation, or manufacturing, SCADA systems serve as the central nervous system of industrial processes.

What is SCADA?

SCADA is not a single piece of software or equipment, but a complete system architecture. It combines sensors, controllers, communication networks, and user interfaces to deliver one goal: real-time visibility and control.

-

Sensors & Field Devices: Instruments in the field measure conditions like temperature, pressure, flow, or position.

-

PLCs and RTUs: Programmable logic controllers (PLCs) and remote terminal units (RTUs) collect sensor data and send commands back to machines.

-

Communication Networks: These devices talk to the central system via wired or wireless links using standard protocols.

-

Central Soft

ware: SCADA software visualizes the data in dashboards and alarms, enabling operators to monitor and adjust processes.

ware: SCADA software visualizes the data in dashboards and alarms, enabling operators to monitor and adjust processes.

The result is a live picture of industrial operations, complete with control tools to keep systems running smoothly and safely.

Why It Matters

Without SCADA, operators would be blind to what’s happening across large or complex facilities. Instead of waiting for a machine to fail, SCADA makes it possible to:

-

Detect issues early through alarms

-

Adjust processes remotely

-

Record historical data for compliance and optimization

-

Improve uptime and efficiency

Where AIDC Comes In

Automatic Identification & Data Capture (AIDC) technologies—like barcoding and RFID—add another layer to this visibility. While SCADA handles process control, AIDC provides product identity. By integrating the two, industries gain a powerful combination:

-

Traceability: Every item or batch can be tracked through SCADA’s historical logs.

-

Validation: Processes only continue when the correct barcode or RFID tag is confirmed.

-

Error Reduction: A mismatch between product identity and process triggers immediate alerts.

The Bigger Picture

Together, SCADA and AIDC give companies more than just control—they deliver confidence. Not only are the machines running as intended, but the right products are in the right place at the right time. This integration is shaping the future of smart automation, making operations both more resilient and more intelligent. The global SCADA market is projected to grow at a robust rate – from around USD 12.9 billion in 2025 to USD 20.05 billion by 2030, driven by rising demand for automation, smart control, and real-time monitoring across utilities, manufacturing, oil & gas, and other critical infrastructure.