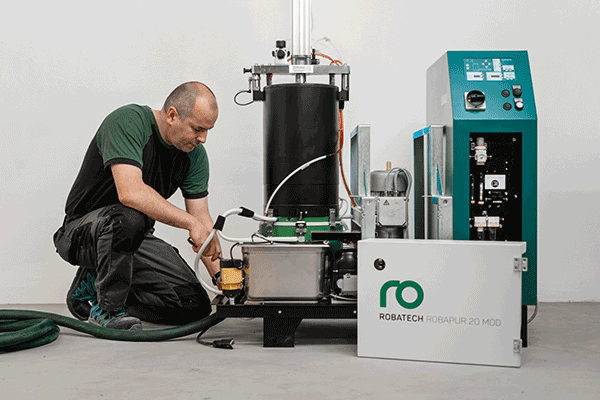

At IBC International Bar Coding, we are proud to announce that we now offer comprehensive service and support for industrial hot-melt glue dispensing systems, including solutions from industry leaders Nordson and Robatech. Whether you’re utilizing hot-melt tanks, hoses and applicators, or precision bead, swirl or jet-glue technologies, our experienced team can help you maintain, optimize, and expand your system performance.

Our scope of service includes:

-

Preventative maintenance and calibration of hot-melt melters, hoses and applicators — including wear-parts replacement and thermal system checks.

-

Troubleshooting adhesive application issues such as stringing, tailing, inconsistent bead patterns or downtime.

-

Upgrades and retro-fits to modern guns/applicators (for example Nordson’s MiniBlue® II, PatternJet®, or Robatech’s tank-less Concept systems) to support high-speed, high-precision lines.

-

System integration and consultation: We assist in matching the right melter, applicator and control strategy for your packaging, converting or assembly line — drawing on the deep global expertise of Nordson and Robatech.

-

On-site support across Canada and The United States. We coordinate with manufacturers’ service networks and provide rapid response.

Why choose IBC International Bar Coding? We combine adhesive-system expertise with bar-coding and automation knowledge, so you get a holistic approach to your production line. Whether you need to seal cases, stabilize pallets, apply adhesive to non-wovens or assemble components, we ensure the glue-application side runs seamlessly within your workflow.

_________________________________________________________________________________________________________________________________

Ready to upgrade or service your hot-melt glue system? Contact us today for a free assessment and quotation. Let us keep your glue-application line running reliably and efficiently — get in touch with IBC International Bar Coding now.